Alexander Rainer

If you’ve read the article in January about 3D printing, and are feeling enthused to try it, you may be wondering how to get an object into a format that can be printed on a 3D printer. Well there are two ways: You can spend hours of time meticulously building a CAD model of your part…or you could turn to 3D scanning to capture your model and generate a model for you.

Figure 1- A 3D model of the Hulk [1]

Figure 1- A 3D model of the Hulk [1]

3D scanning has been around for a while and has been steadily maturing in the shadow of its sister technology 3D printing, to the extent that it is routinely used by industries working in medicine, aerospace and the latest computer graphics to enable them to stay at the forefront of technology. For a long time this equipment was only available to companies with deep pockets; however, technological advances have made the price of this equipment much more affordable. So much so, that there are even scanners even available to the home hobbyist who seeks to dabble in 3D modelling (Makerbot Digitiser, Scanify and Cubify Sense).

But what is a 3D scanner? Put simply, it is a camera that captures the 3D geometry it sees and turns it into a 3D model that is dimensionally congruent with the original. These scanners rely on two distinct scanning technologies: laser or structured white light. Here, one or more angled cameras monitor the distortion of a laser line, or structured white light grid projected across the object being inspected, to read in the real geometry. These scanners can be deployed in several ways dependent on the size of the object. Small objects can be scanned by a fixed scanner with a turntable, whereas larger objects can be scanned in situ using a metrology arm based scanner or a freehand based scanner. Laser scanners coupled to a metrology arm typically offer the highest resolution and are used when only the most accurate scans will do.

Figure 2 – Konica Minolta Vivid 9i Fixed Position Laser Scanner, Romer Absolute Arm Laser Scanner & an Artec Space Spider Freehand Structure White Light Scanner

Having selected the right scanner for the task, lifelike digital models can be created. What you do with the model next is almost limitless and you are not limited to 3D printing only. In fact, these scanners are being used in an assortment of different ways.

Metrology:

Certain industries use 3D scanners to capture measurements from complex geometry, such as the tyre tread across a tyre or the corrosion pitting across cast iron pipe. Better informed metrology is achieved since the number of measurements taken increases as the scanner can rapidly sample the whole object.

Figure 3 – Scanning the inside of an old cast iron water main

Quality Assurance:

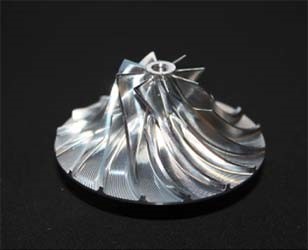

Higher quality parts result from tighter tolerances, however, measuring to these levels is challenging particularly if the geometry is complex, such as a turbo compressor wheel. 3D scanning allows an accurate model of this geometry to be captured quickly and then compared to the original CAD design. This analysis can identify any parts that are out of tolerance and even identify errors in the manufacturing process that occur repeatedly.

Figure 4 – Example of a Prae-Turbo Compressor Wheel [2]

Reverse Engineering:

3D scanners are used heavily for part replication since a 3D model can be easily sent to a 3D printer, but scanned models can also be converted into a CAD model of the component using technical software. This is particularly useful when doing restoration projects which need bespoke components which are no longer manufactured or have no drawings. Furthermore, these components can even be modified if further functionality is needed.

CGI:

Not all 3D scanning is focused on metrology. In fact, some applications are more focused on the ability to create a realistic rendered 3D model. For example, CGI companies have adopted 3D scanners as a method of creating a 3D computer model of actors, exploiting the ability to texturise a 3D model. Capturing raw models that are true to life ensures that all computer simulations look frighteningly real. Further, the models can be manipulated on a computer, thus allowing the scene to be reshot many times at a fraction of the cost of doing it in reality.

The use of 3D scanning continues to grow and is potentially endless. Here I have described but a few uses for the 3D scanner which in themselves are very diverse areas. In fact, the sky is the limit for 3D scanning. If you need to make a 3D model, or have complex geometry you need to measure, 3D scanning may be the answer you have been searching for.

References

[1] – http://www.thingiverse.com/thing:993933

[2] – http://www.prae-turbo.de/impellers.php

Further Viewing

Jay Leno – showing a Faro 3D scanner copying a rare car part

Applications of Artec 3D scanners

Applications of Creaform 3D scanners